How to ensure the even distribution of glue in the glue dispenser

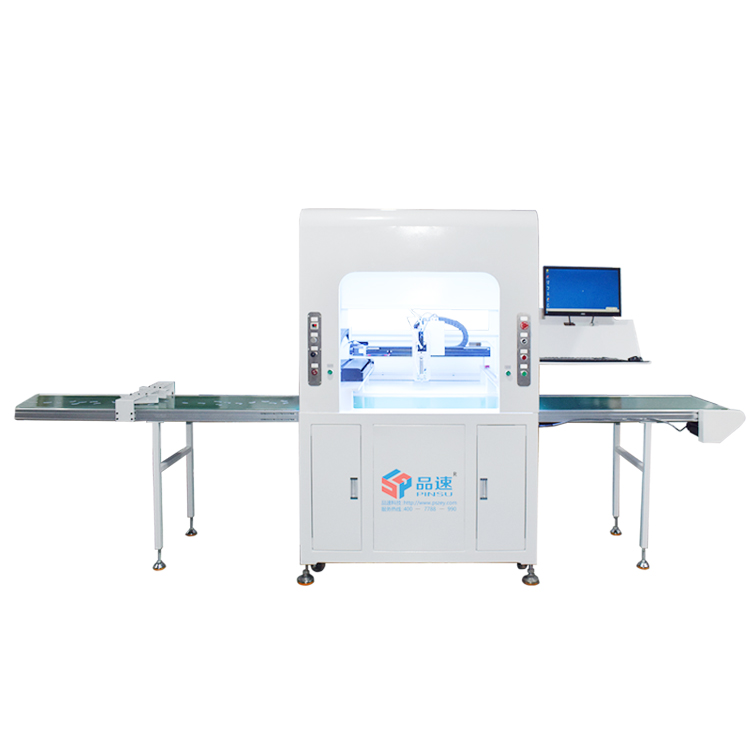

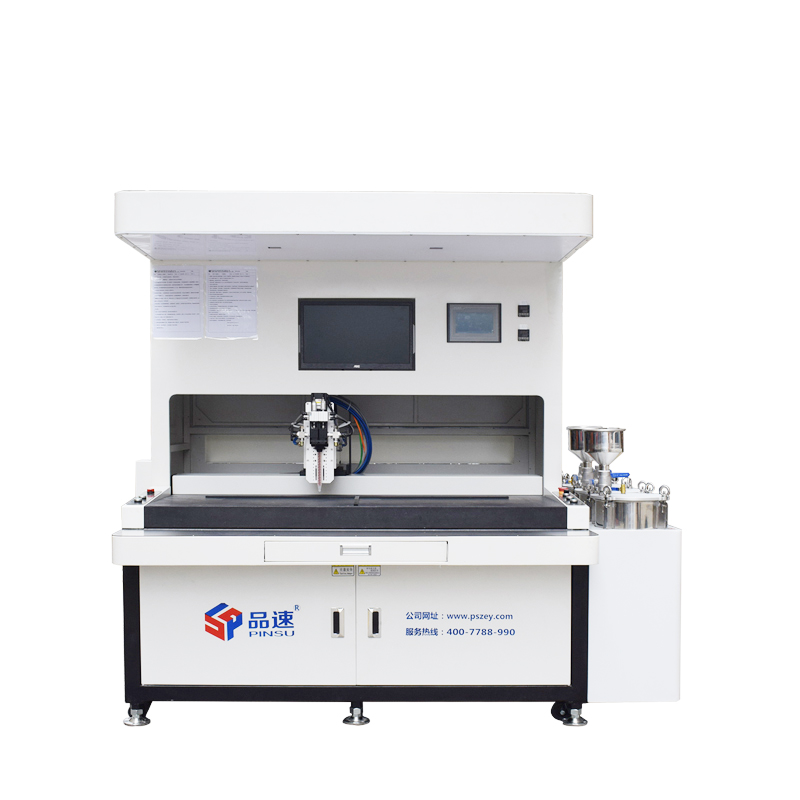

When using the glue filling machine, how to maintain the uniform distribution of glue is very important, which directly affects the quality and performance of the glue filling product. The following are some methods of using glue evenly distributed in the small weaving and finishing of glue filling machine.

1. Ensure proper functioning of the Potting Machine. Before use, the glue filling machine shall be fully inspected, including cleaning of glue filling equipment, smoothness of pipes and normal supply of glue. Any problem in any link may lead to uneven glue distribution.

2. The property of glue is also an important factor affecting the uniform distribution. When selecting glue, select the appropriate glue according to the requirements of the product and the characteristics of the glue filling machine. For example, the viscosity and mobility of glue will affect its distribution on the product.

3. Potting machine operation techniques are also essential. In the process of glue filling, the speed and pressure of glue filling shall be well controlled to avoid uneven glue distribution caused by too fast or too slow glue filling. At the same time, pay attention to the angle and position of glue pouring to ensure that the glue can evenly cover the surface of the product.

4. Regular maintenance of the glue filling machine is also the key to ensure even distribution of glue. Regularly clean the pipes, nozzles and other parts of the glue filling machine to ensure that they are unobstructed. At the same time, check whether the parameters of the machine are normal, and adjust them if necessary.

5. The professional quality of workers also has an important impact on the uniform distribution of glue. The operator shall be familiar with the operation process and precautions of the glue filling machine, and have a certain technical level and sense of responsibility.

In a word, the uniform distribution of glue needs to start from the operation of glue filling machine, glue selection, operation skills, maintenance and personnel quality. Only when each link is strictly controlled, can the glue be evenly distributed, so as to improve the quality and performance of the product.

1. Ensure proper functioning of the Potting Machine. Before use, the glue filling machine shall be fully inspected, including cleaning of glue filling equipment, smoothness of pipes and normal supply of glue. Any problem in any link may lead to uneven glue distribution.

2. The property of glue is also an important factor affecting the uniform distribution. When selecting glue, select the appropriate glue according to the requirements of the product and the characteristics of the glue filling machine. For example, the viscosity and mobility of glue will affect its distribution on the product.

3. Potting machine operation techniques are also essential. In the process of glue filling, the speed and pressure of glue filling shall be well controlled to avoid uneven glue distribution caused by too fast or too slow glue filling. At the same time, pay attention to the angle and position of glue pouring to ensure that the glue can evenly cover the surface of the product.

4. Regular maintenance of the glue filling machine is also the key to ensure even distribution of glue. Regularly clean the pipes, nozzles and other parts of the glue filling machine to ensure that they are unobstructed. At the same time, check whether the parameters of the machine are normal, and adjust them if necessary.

5. The professional quality of workers also has an important impact on the uniform distribution of glue. The operator shall be familiar with the operation process and precautions of the glue filling machine, and have a certain technical level and sense of responsibility.

In a word, the uniform distribution of glue needs to start from the operation of glue filling machine, glue selection, operation skills, maintenance and personnel quality. Only when each link is strictly controlled, can the glue be evenly distributed, so as to improve the quality and performance of the product.

中文

中文