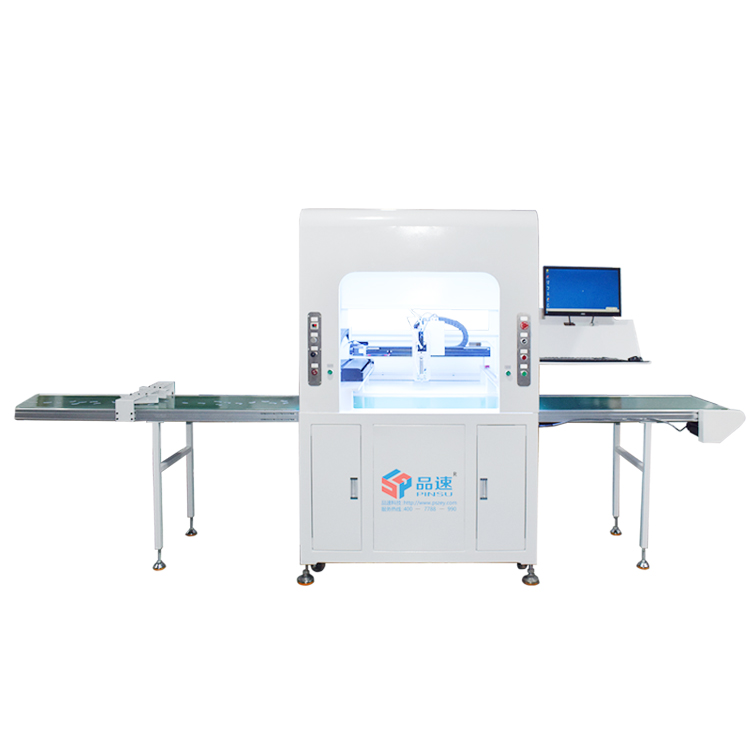

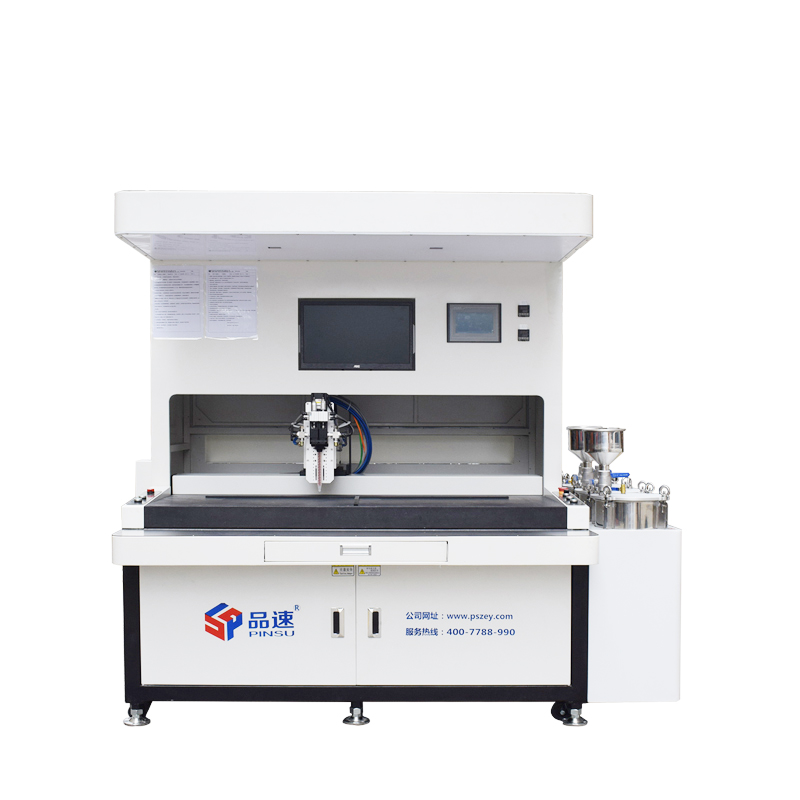

Operation Process of Dispenser and Attentions in Use

The use of glue filling machine promotes the industrialization process and greatly improves the production efficiency. How to operate the glue filling equipment for the first time? What are the issues to note? Let's learn about it by the editor.

I Starting process of glue filling equipment

1. Check the glue filling area. Sundries and tools must be cleaned.

Check whether the compressed air is within the normal range and whether the power supply meets the requirements.

Power on the machine.

Before installing the mixing pipe, check whether the action of the double liquid valve is normal and whether the glue is discharged accurately. If the glue used is different from the previous one, the proportional adjustment is required.

When the mixing pipe is installed, test whether the dynamic mixing is normal. Meanwhile, discharge AB glue and confirm that the mixing pipe is full and free of bubbles.

Place the product, edit the program or start position, and verify whether the three-axis running path meets the requirements.

Press the "glue filling" button on the main screen to display "glue opening", press the green start button to start production, press the green button again to pause, and press the emergency stop button in case of emergency.

II Shutdown process

If the circulation function is turned on, the circulation function is turned off when the last product is filled with glue.

If automatic cleaning function is available, run automatic cleaning. If there is no automatic cleaning function, remove the mixing pipe, apply AB glue for 3-5 seconds, and wipe the dual liquid valve head with a rag.

Turn off the power supply, clean the machine, clean the mixing pipe, etc.

III Pause the operation

1. If the cycle function is turned on, the cycle function will be turned off when the last product is filled with glue.

Start the automatic adhesive discharge function, pay attention to the automatic adhesive discharge time, and discharge the adhesive before the adhesive becomes thick.

IV Precautions during glue filling of glue filling machine

Before installing the "mixing pipe", enter the "dispensing screen" to check whether the AB glue is discharged smoothly and correctly.

Check whether the "mixing tube, spiral blade, needle and nozzle" are clean and whether they are blocked by foreign matters.

Before the product is filled with glue, record the glue amount of AB mixed glue for 5s. Check whether the weight of AB glue is consistent with the recorded value every two hours during glue filling of the product. If the change is too large, immediately shut down the machine for inspection, otherwise the glue may not be dried.

Pay close attention to the amount of gum in the AB glue bucket. If there is no glue in the AB glue bucket, the glue supply part will be damaged.

Place the product on the fixture in the same position.

Based on the curing time of the glue, the glue shall be filled for more than 15 minutes, and the output weight of AB mixed glue shall be checked when the glue is recovered.

Pause glue filling for more than 30 minutes according to the curing time of glue, and remove the mixing pipe for cleaning.

中文

中文