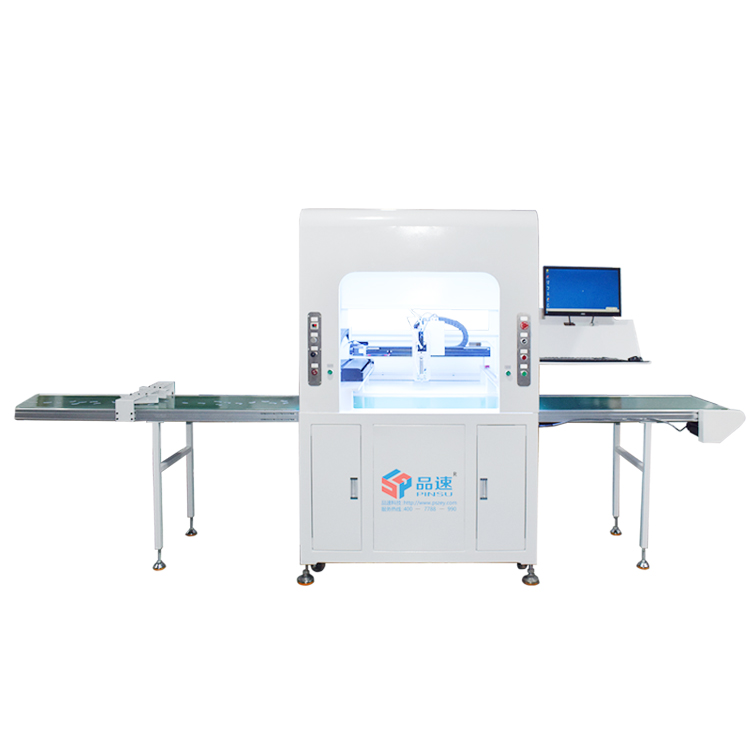

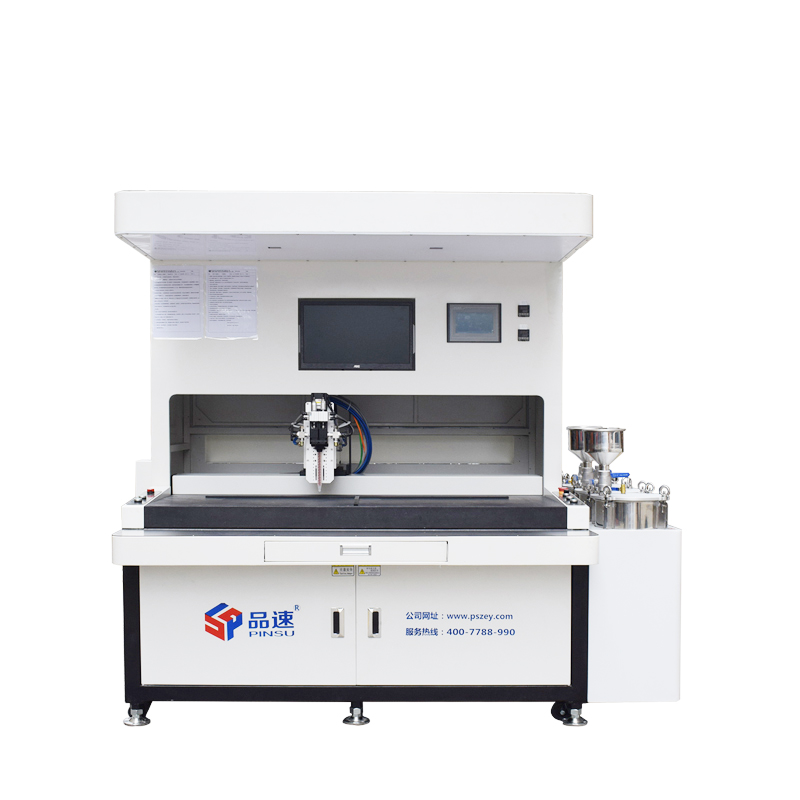

What are the common consumables of automatic glue filling machine

The emergence of glue filling machine greatly promotes the production efficiency. Of course, we need to know the daily maintenance of glue filling machine. What are the daily consumables of double liquid glue filling machine? Let's learn about it by the editor.

First, the mixing pipe under the rubber valve. The mixing tube can be divided into dynamic and static types. The spiral mixing core in the mixing tube will deform and form burrs when cutting the glue for a long time. At this time, it needs to be replaced. The static mixing tube can be used for a long time, generally for 15 to 30 days. The time of the dynamic tube is relatively shorter. The mixing core in the dynamic mixing tube is driven by the brushless motor to rotate at high speed, which can reach 1200 times per minute. Therefore, the deformation is faster, and it needs to be replaced in 7 to 15 days.

To reduce costs, some glues are used to increase heat transfer, some of which add filler to the glue to increase hardness, some of which are in the form of powder, some are granular, and some are very rigid. For example, if the filler is ceramic powder, alumina, etc., the long-term friction between the filler in the glue and the seal ring will cause the wear of the seal ring, and the wear of the seal ring will cause the glue unable to be received. In this case, we must replace the seal ring, and under normal circumstances, replace it once a month or two. If the glue pack is too much, sometimes the seal may be replaced within half a month. Like 1:1 thick glue packing will be more, the replacement of seal ring is faster.

First, the mixing pipe under the rubber valve. The mixing tube can be divided into dynamic and static types. The spiral mixing core in the mixing tube will deform and form burrs when cutting the glue for a long time. At this time, it needs to be replaced. The static mixing tube can be used for a long time, generally for 15 to 30 days. The time of the dynamic tube is relatively shorter. The mixing core in the dynamic mixing tube is driven by the brushless motor to rotate at high speed, which can reach 1200 times per minute. Therefore, the deformation is faster, and it needs to be replaced in 7 to 15 days.

To reduce costs, some glues are used to increase heat transfer, some of which add filler to the glue to increase hardness, some of which are in the form of powder, some are granular, and some are very rigid. For example, if the filler is ceramic powder, alumina, etc., the long-term friction between the filler in the glue and the seal ring will cause the wear of the seal ring, and the wear of the seal ring will cause the glue unable to be received. In this case, we must replace the seal ring, and under normal circumstances, replace it once a month or two. If the glue pack is too much, sometimes the seal may be replaced within half a month. Like 1:1 thick glue packing will be more, the replacement of seal ring is faster.

中文

中文