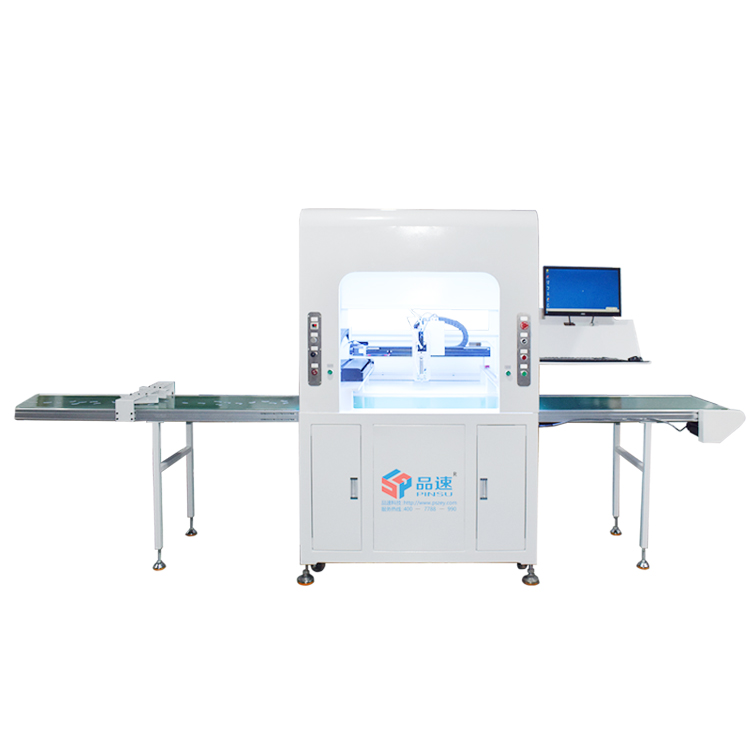

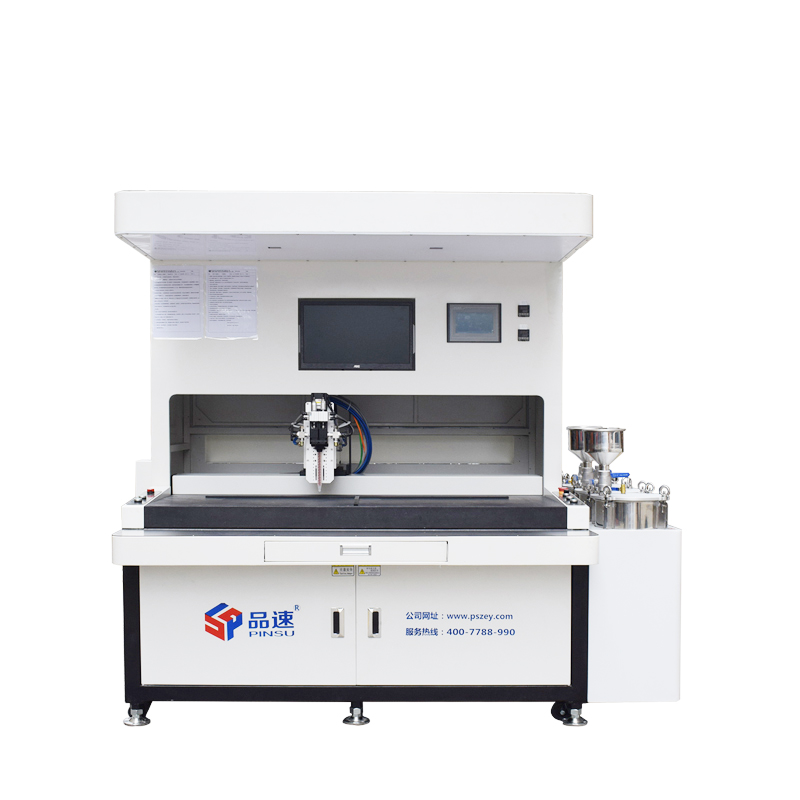

Commissioning of visual potting machine before production

When the visual filling machine is installed by the visual filling machine manufacturer according to the customized standard of the customer, it will tell the special machine dispatcher to do the debugging, which is usually called the test machine. The customer products must be prepared in advance before the test machine, and then the machine dispatcher will do the test machine according to the control jig program and the specific position of the needle of the visual dispensing machine.

1. Turn on the switch power of the visual dispensing machine, enter the system interface, and set the values of X, Y and Z axis according to the path of the customer's product. The values include the specific dispensing position, speed and dispensing status; Get adapted to the alignment and enter the system for automatic dispensing. The debugging and programming data information of the visual dispensing machine will be automatically stored and usually not need to be set again. When dispensing with different fluid products, only the corresponding parameters must be different. The actual operator only had to replace the needle, replace the glue and remove the finished product.

2. For the commissioning of the visual dispensing machine, the first thing we should do is to adjust the needle. Use the keyboard up, down, left and right movement keys for calibration. After the needle is aligned, press the OK key to complete the needle alignment operation. That is to say, the X axis and Y axis are set, while the Z axis is matched with the vertical distance. According to the operation prompts on the operation interface, do a good job in the lifting and lowering movement of the Z axis. The height of the Z axis should be calibrated before each injection.

The above is about the preparation for the commissioning of visual glue filling machine before production. Only in this way can our glue filling production be carried out smoothly. At the same time, good commissioning of equipment can also improve the yield of products, thus improving the overall production efficiency.

1. Turn on the switch power of the visual dispensing machine, enter the system interface, and set the values of X, Y and Z axis according to the path of the customer's product. The values include the specific dispensing position, speed and dispensing status; Get adapted to the alignment and enter the system for automatic dispensing. The debugging and programming data information of the visual dispensing machine will be automatically stored and usually not need to be set again. When dispensing with different fluid products, only the corresponding parameters must be different. The actual operator only had to replace the needle, replace the glue and remove the finished product.

2. For the commissioning of the visual dispensing machine, the first thing we should do is to adjust the needle. Use the keyboard up, down, left and right movement keys for calibration. After the needle is aligned, press the OK key to complete the needle alignment operation. That is to say, the X axis and Y axis are set, while the Z axis is matched with the vertical distance. According to the operation prompts on the operation interface, do a good job in the lifting and lowering movement of the Z axis. The height of the Z axis should be calibrated before each injection.

The above is about the preparation for the commissioning of visual glue filling machine before production. Only in this way can our glue filling production be carried out smoothly. At the same time, good commissioning of equipment can also improve the yield of products, thus improving the overall production efficiency.

中文

中文