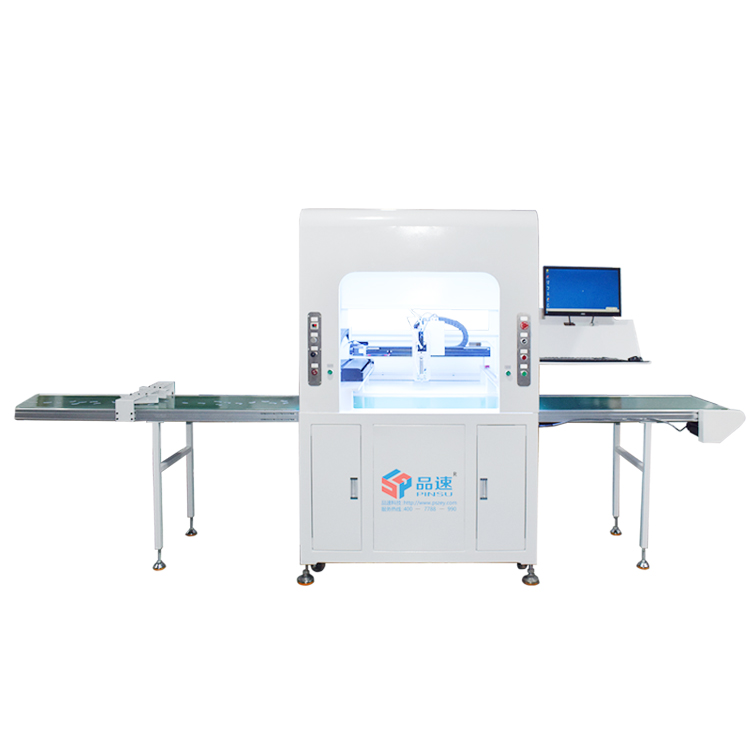

How to detect glue B of automatic glue filling machine

Glue commonly used in glue dispenser is AB glue, which will be solidified only when two glues are mixed together. Wherein, adhesive A is the agent, adhesive B is the curing agent, adhesive B plays a catalytic role. Without adhesive B, the glue will not dry. If the amount of adhesive B is not enough, the glue will not dry. If the amount of adhesive B is too much, the glue will cure too fast

In the process of glue filling, some customers found that the glue filling was not dry and the product was scrapped because the amount of glue B was less. Why is the amount of B glue reduced? How do I monitor this? The most common reason is that the curing agent crystallizes and blocks, causing B glue not to come out.

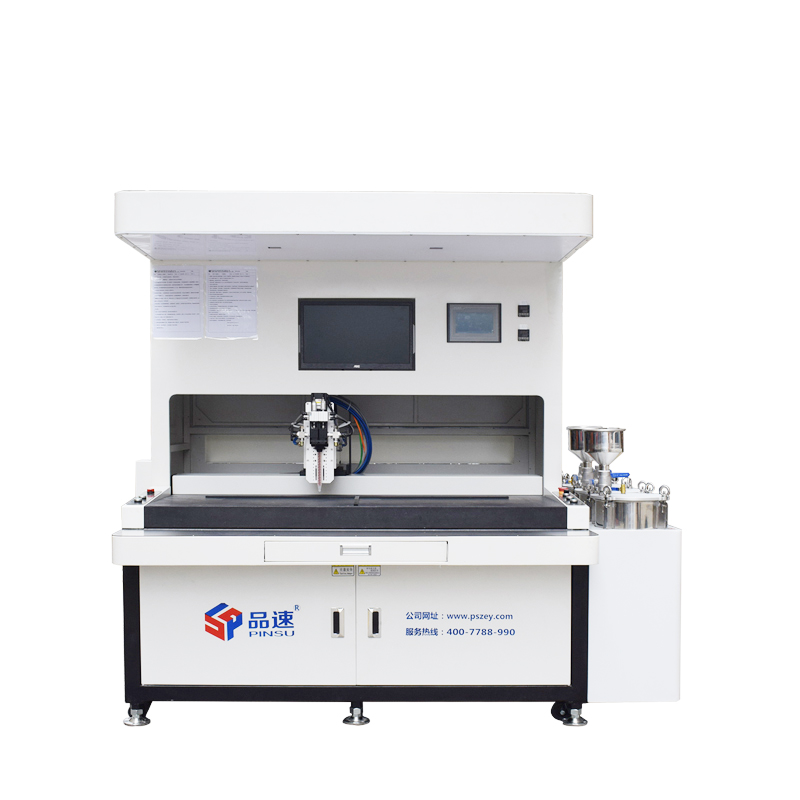

There are three solutions to the problem of B glue amount:

1、 The most perfect solution, but the cost is high. A digital flowmeter is installed at the connection between the B glue pipe and the pump body. When the B glue flow is lower than the set value, the glue dispenser will alarm and stop. The digital flowmeter can be used to monitor the amount of B glue at any time, so as to achieve a very safe effect.

2、 Low-cost solution, add pressure sensor at the connection between B rubber pipe and pump body. When the pipe is blocked, the pressure of the glue will increase and the machine will alarm and stop, but this is also defective. If the pipe is seriously blocked or completely blocked, the pressure sensor can play a good role. If only a little is blocked, the pressure sensor may not be able to detect if there is very little blocking.

3、 It is also a low-cost solution. A simple flowmeter is installed at the head. The flowmeter is intuitive and has a floating ball. When B glue is normal, the floating ball will move up and down. When B glue is not out, the floating ball will not move, or when the amount is small, the floating ball will move slowly. This defect is the same as the pressure sensor, and cannot be detected when only a little is blocked.

The above is the monitoring method for B glue of glue filling machine. B glue is very important to the glue filling of the product, and solving the glue discharging problem of B glue is an important step in the glue filling process of the product.

In the process of glue filling, some customers found that the glue filling was not dry and the product was scrapped because the amount of glue B was less. Why is the amount of B glue reduced? How do I monitor this? The most common reason is that the curing agent crystallizes and blocks, causing B glue not to come out.

There are three solutions to the problem of B glue amount:

1、 The most perfect solution, but the cost is high. A digital flowmeter is installed at the connection between the B glue pipe and the pump body. When the B glue flow is lower than the set value, the glue dispenser will alarm and stop. The digital flowmeter can be used to monitor the amount of B glue at any time, so as to achieve a very safe effect.

2、 Low-cost solution, add pressure sensor at the connection between B rubber pipe and pump body. When the pipe is blocked, the pressure of the glue will increase and the machine will alarm and stop, but this is also defective. If the pipe is seriously blocked or completely blocked, the pressure sensor can play a good role. If only a little is blocked, the pressure sensor may not be able to detect if there is very little blocking.

3、 It is also a low-cost solution. A simple flowmeter is installed at the head. The flowmeter is intuitive and has a floating ball. When B glue is normal, the floating ball will move up and down. When B glue is not out, the floating ball will not move, or when the amount is small, the floating ball will move slowly. This defect is the same as the pressure sensor, and cannot be detected when only a little is blocked.

The above is the monitoring method for B glue of glue filling machine. B glue is very important to the glue filling of the product, and solving the glue discharging problem of B glue is an important step in the glue filling process of the product.

中文

中文