What are the advantages of a fully automatic vacuum filling machine?

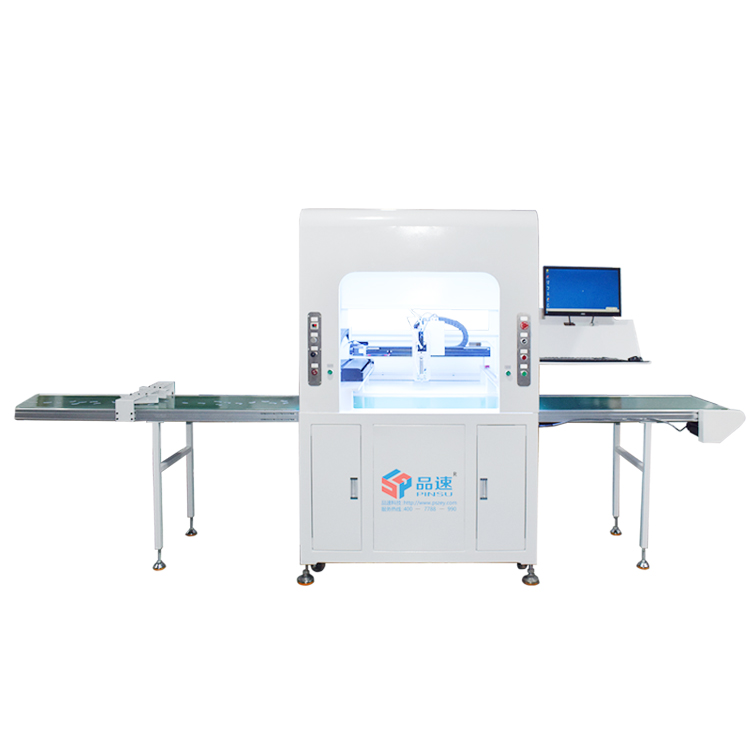

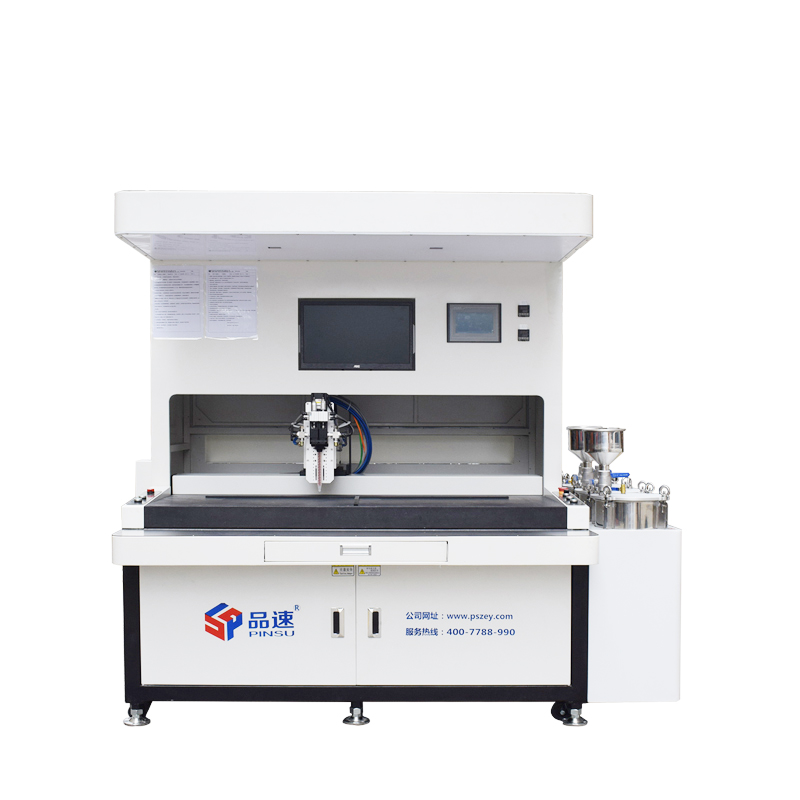

The automatic vacuum glue filling machine is an advanced equipment integrating material supply, heating, mixing, glue filling and other functions. It adopts advanced control system and technology to realize full-automatic operation in the glue filling process, greatly reducing the difficulty and risk of manual operation, and greatly improving the production efficiency. Compared with the traditional manual or semi-automatic glue filling method, the automatic vacuum glue filling machine has more advantages.

First of all, the automatic vacuum glue filling machine can realize high-speed glue filling, greatly improving the production efficiency. It adopts a fully automatic operation mode, which can quickly and accurately complete the glue pouring process. Moreover, the automatic vacuum glue filling machine is equipped with advanced feeding device and pipeline design, which can efficiently convey glue and ensure the even mixing of glue. In this way, enterprises can greatly shorten the production cycle, quickly respond to market demands, and improve the delivery speed and supply capacity of products.

Secondly, the automatic vacuum filling machine has the characteristics of accurate control to ensure the accuracy of the filling process. Through advanced sensor and control system, the automatic vacuum glue filling machine monitors and controls various parameters in the glue filling process, such as glue temperature, glue amount, pressure, etc. to ensure the accuracy and stability of every glue filling. Compared with the traditional manual glue filling method, the automatic vacuum glue filling machine can more accurately control the flow and distribution of glue, so as to ensure the accuracy and consistency of the product.

In addition, the automatic vacuum filling machine has the characteristics of friendly human-machine interface and easy operation. It adopts the advanced touch screen control system to clearly and intuitively display the process parameters and operating steps. The operator can easily complete the glue filling process by simply setting and adjusting according to the system prompts. In addition, the automatic vacuum filling machine also has fault self-diagnosis and alarm functions, which can timely find and solve potential problems, reduce the need for manual intervention, and improve the stability and reliability of the equipment.

In a word, the automatic vacuum glue filling machine is the ideal choice for enterprises to realize efficient and accurate glue filling. With its high speed and precision, it can greatly improve production efficiency and product quality. Compared with the traditional manual or semi-automatic glue filling method, the automatic vacuum glue filling machine has higher controllability, stability and consistency, which can meet the requirements of enterprises for glue filling process. In the future industrial production, the automatic vacuum glue filling machine will play an increasingly important role to help enterprises realize efficient and accurate glue filling, thereby improving competitiveness and winning more business opportunities.

中文

中文