Principle and Application of Static Mixing Tube

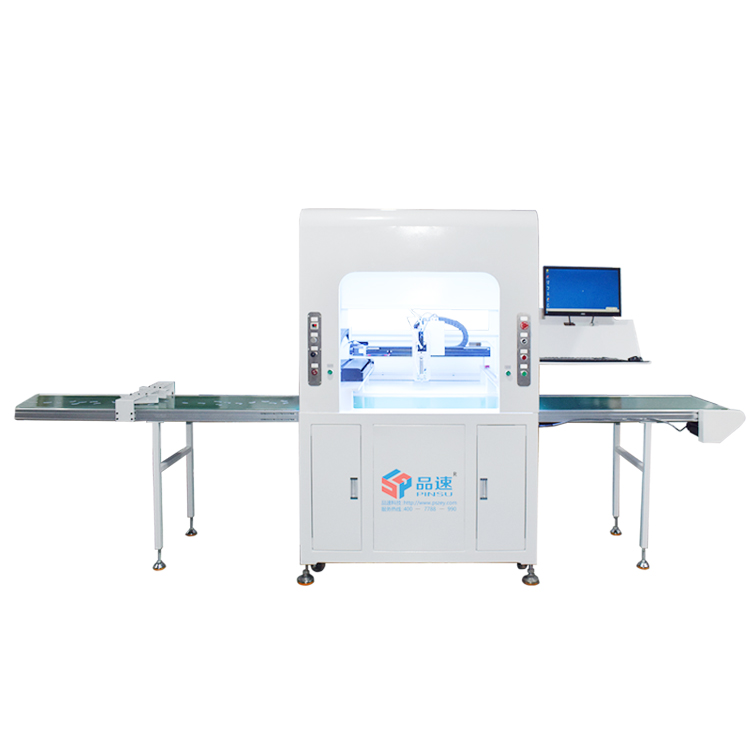

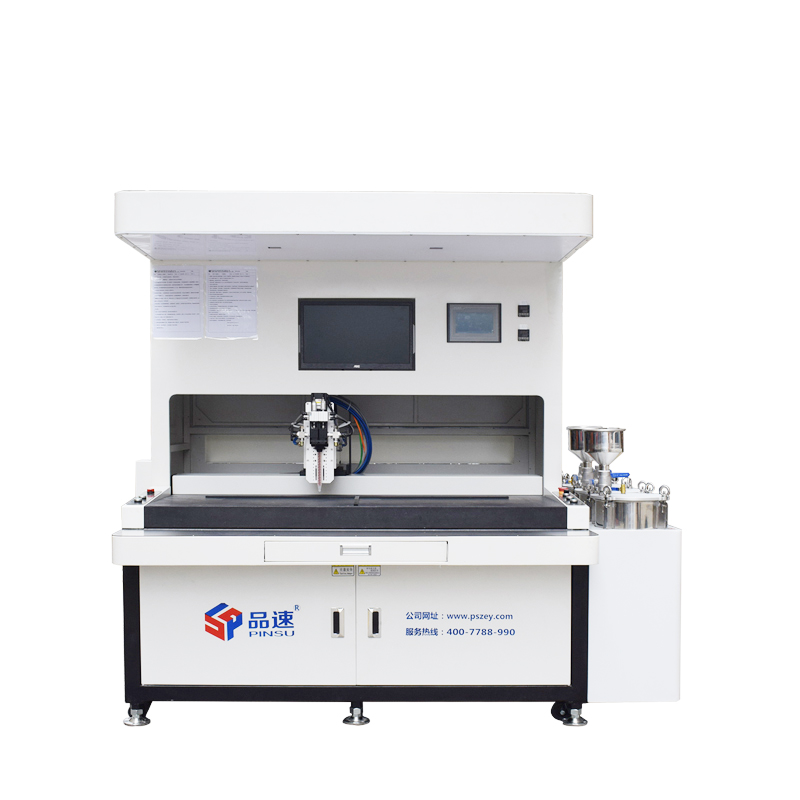

With the rapid development of the glue filling equipment, the performance of the double liquid glue filling machine is also continuously improved. Let's learn the function and principle of the static mixing tube in the double liquid glue filling machine by the small braiding tape, so that we can further understand the internal structure of the glue filling machine.

The static mixing tube of double liquid glue filling machine is composed of a series of left-right rotating blades vertically arranged in the casing in order. When the fluid itself passes through the mixer, the static mixing pipe is continuously cut and overlapped to convert more than two kinds of materials into a uniform mixture.

The square static mixing pipe is an efficient, economical and durable high-end product improved and innovated on the basis of the circular static mixing pipe. Its principle is composed of upper, lower, left and right blades arranged in order. When more than two kinds of fluid pass through each blade, it will be cut into 4 parts, while the circular static mixing pipe can only cut the fluid into 2 parts. Therefore, it is twice the mixing uniformity of the circular static mixing pipe, so that the fluid mixing is more uniform. Since its blades are arranged in a natural and orderly manner, the resistance of the square static mixing pipe is at least 1/3 less than the circular static mixing pipe, reducing the external force driving and achieving a very good cost reduction effect.

When the square static mixing pipe is stopped, the residual liquid adhered in the square static mixing pipe will be more than 1/3 less than the circular static mixing pipe, greatly reducing the use cost of raw materials. Therefore, the square static mixing pipe can reduce the waste of raw materials, reduce the cost of external driving and greatly improve the mixing effect of raw materials, thereby reducing the defect rate of products and improving the production efficiency.

The use of a static mixing tube for a dual liquid applicator provides a low-cost solution for dual component liquid mixing. The static mixing tube can save labor, reduce waste, greatly improve productivity and reduce production cost. The device can be used for the mixing of various two-component adhesives and fillers, such as AB epoxy resin, AB silica gel, AB polyurethane, PU adhesive, crystal adhesive, etc.

The static mixing tube of double liquid glue filling machine is composed of a series of left-right rotating blades vertically arranged in the casing in order. When the fluid itself passes through the mixer, the static mixing pipe is continuously cut and overlapped to convert more than two kinds of materials into a uniform mixture.

The square static mixing pipe is an efficient, economical and durable high-end product improved and innovated on the basis of the circular static mixing pipe. Its principle is composed of upper, lower, left and right blades arranged in order. When more than two kinds of fluid pass through each blade, it will be cut into 4 parts, while the circular static mixing pipe can only cut the fluid into 2 parts. Therefore, it is twice the mixing uniformity of the circular static mixing pipe, so that the fluid mixing is more uniform. Since its blades are arranged in a natural and orderly manner, the resistance of the square static mixing pipe is at least 1/3 less than the circular static mixing pipe, reducing the external force driving and achieving a very good cost reduction effect.

When the square static mixing pipe is stopped, the residual liquid adhered in the square static mixing pipe will be more than 1/3 less than the circular static mixing pipe, greatly reducing the use cost of raw materials. Therefore, the square static mixing pipe can reduce the waste of raw materials, reduce the cost of external driving and greatly improve the mixing effect of raw materials, thereby reducing the defect rate of products and improving the production efficiency.

The use of a static mixing tube for a dual liquid applicator provides a low-cost solution for dual component liquid mixing. The static mixing tube can save labor, reduce waste, greatly improve productivity and reduce production cost. The device can be used for the mixing of various two-component adhesives and fillers, such as AB epoxy resin, AB silica gel, AB polyurethane, PU adhesive, crystal adhesive, etc.

中文

中文