What to Know When Choosing a Vacuum Glue Filling Machine

In the field of industrial manufacturing, the importance of vacuum glue filling machines is increasingly prominent. However, how to choose a vacuum glue filling machine that suits one's needs has become a headache for many friends.

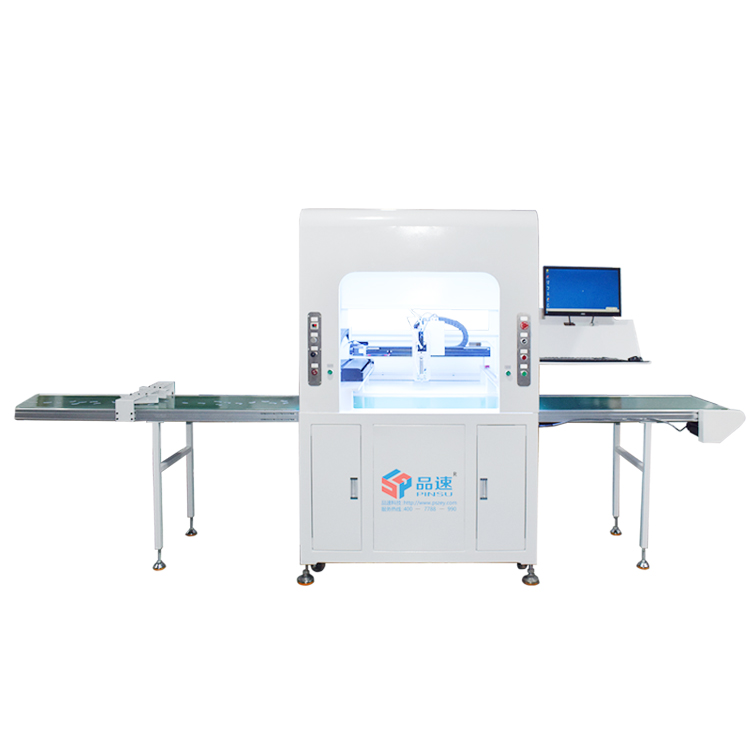

Firstly, clarify the production scale and output requirements. You need to first calculate how many products your production line needs to process each day. If the output is large, you have to choose the kind of big guy with high efficiency and strong stability; If the output is small, some small but fully functional machines may be more suitable.

Secondly, there is a requirement for the precision of adhesive filling. This is like a tailor making clothes, the size must be accurate. Different products may have different requirements for adhesive precision. For example, high-end electronic devices may require glue filling equipment with an accuracy of ± 0.1%, while for general industrial products, ± 0.5% may be sufficient.

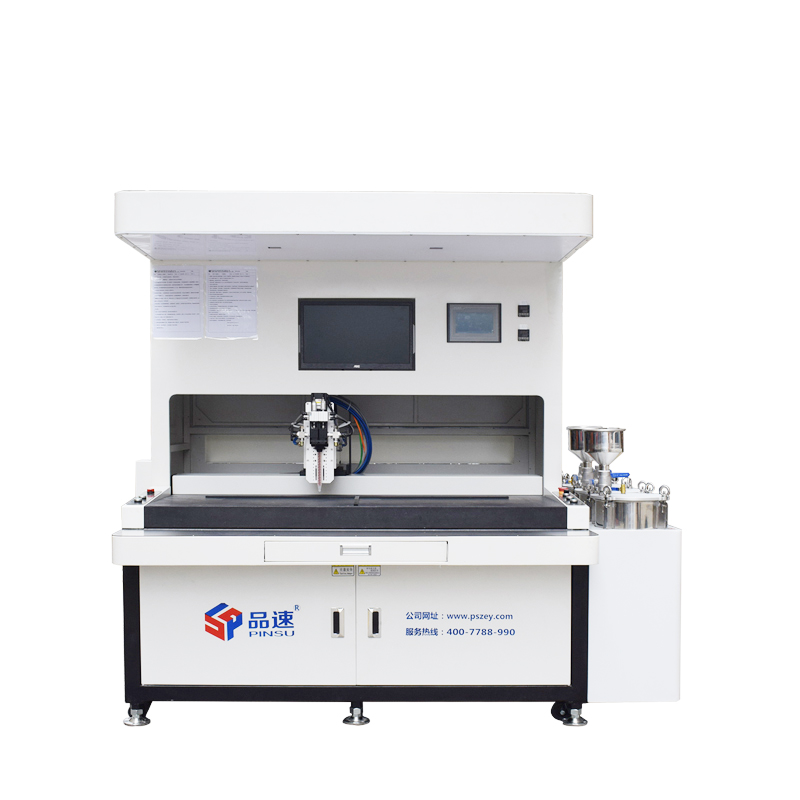

Another thing is the characteristics of the adhesive. Some adhesives have high viscosity, while others are relatively thin, which also has different performance requirements for vacuum glue filling machines. Just like different soils are suitable for growing different crops, choosing the right one can make the glue obedient.

Finally, understand the after-sales service. It is inevitable that the machine will have a "headache", and at this time, the after-sales support of the vacuum glue machine manufacturer becomes crucial. A timely and professional after-sales team can help you avoid many troubles during use.

In short, when choosing a vacuum glue filling machine that suits your needs, you need to comprehensively consider many factors such as production scale, glue filling accuracy, glue characteristics, and after-sales service. Only in this way can this machine become a capable assistant on your production line, creating more value!

Firstly, clarify the production scale and output requirements. You need to first calculate how many products your production line needs to process each day. If the output is large, you have to choose the kind of big guy with high efficiency and strong stability; If the output is small, some small but fully functional machines may be more suitable.

Secondly, there is a requirement for the precision of adhesive filling. This is like a tailor making clothes, the size must be accurate. Different products may have different requirements for adhesive precision. For example, high-end electronic devices may require glue filling equipment with an accuracy of ± 0.1%, while for general industrial products, ± 0.5% may be sufficient.

Another thing is the characteristics of the adhesive. Some adhesives have high viscosity, while others are relatively thin, which also has different performance requirements for vacuum glue filling machines. Just like different soils are suitable for growing different crops, choosing the right one can make the glue obedient.

Finally, understand the after-sales service. It is inevitable that the machine will have a "headache", and at this time, the after-sales support of the vacuum glue machine manufacturer becomes crucial. A timely and professional after-sales team can help you avoid many troubles during use.

In short, when choosing a vacuum glue filling machine that suits your needs, you need to comprehensively consider many factors such as production scale, glue filling accuracy, glue characteristics, and after-sales service. Only in this way can this machine become a capable assistant on your production line, creating more value!

中文

中文