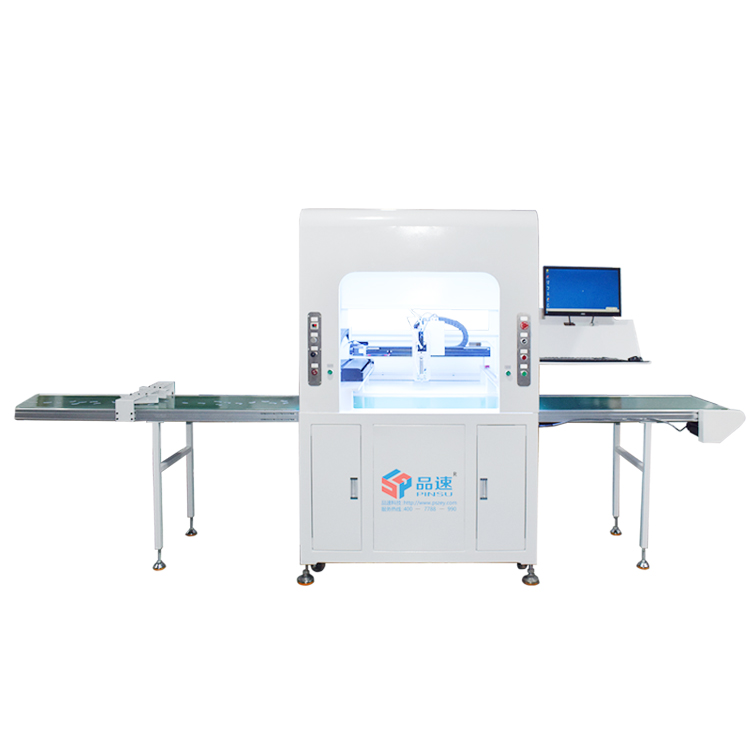

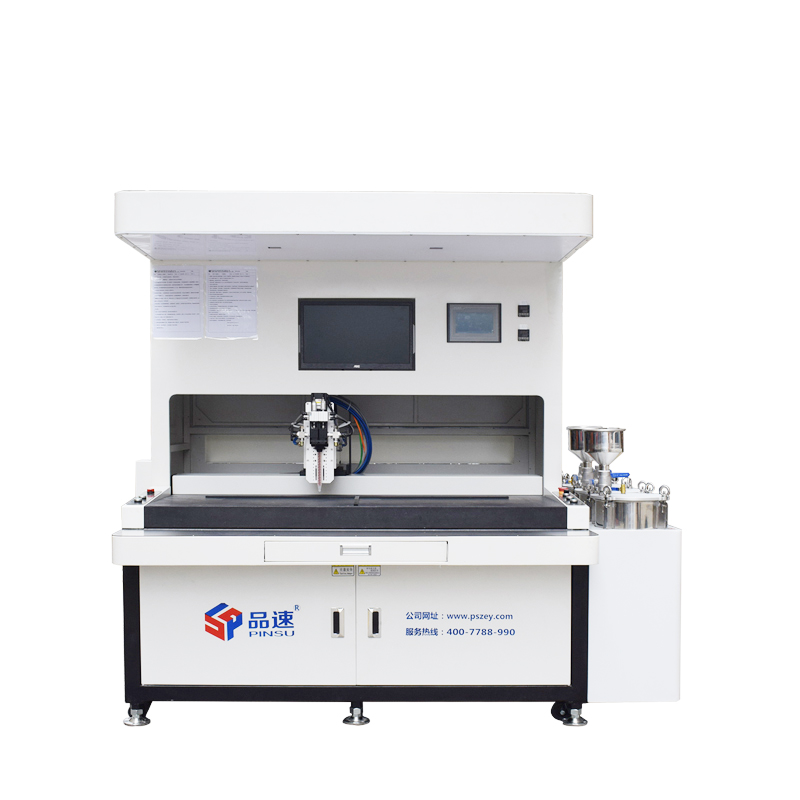

Working Principle of Visual automatic glue filling machine

In modern industrial manufacturing, visual potting machines have become an integral part of many production lines. So how does this mysterious machine work? Let's open its mystery together!

visual inspection and accurate control. Firstly, the visual glue dispenser conducts real-time scanning and image analysis on the products to be glued through the high-precision camera. It is like a pair of "smart eyes", which can quickly and accurately identify the shape, size and position of the workpiece. This is not just a simple "look", but a fine interpretation and judgment of this information through advanced image processing algorithms.

Next, according to the data provided by the visual system, the control system of the glue filling machine will accurately calculate the amount of glue required to be filled for each workpiece, and automatically adjust the position and filling speed of the glue filling head. This is like an accurate "operator", making sure that every drop of glue falls exactly in the right place. In addition, the visual potting machine is highly flexible and adaptive. It can quickly set and adjust parameters according to different workpiece types and glue injection requirements. Whether small electronic components or large mechanical parts, it can be handled easily

In general, visual glue filling machine realizes precise control and automatic operation of glue filling process through visual detection and intelligent control. It not only improves the production efficiency and product quality, but also greatly reduces the error and labor intensity of manual operation.

visual inspection and accurate control. Firstly, the visual glue dispenser conducts real-time scanning and image analysis on the products to be glued through the high-precision camera. It is like a pair of "smart eyes", which can quickly and accurately identify the shape, size and position of the workpiece. This is not just a simple "look", but a fine interpretation and judgment of this information through advanced image processing algorithms.

Next, according to the data provided by the visual system, the control system of the glue filling machine will accurately calculate the amount of glue required to be filled for each workpiece, and automatically adjust the position and filling speed of the glue filling head. This is like an accurate "operator", making sure that every drop of glue falls exactly in the right place. In addition, the visual potting machine is highly flexible and adaptive. It can quickly set and adjust parameters according to different workpiece types and glue injection requirements. Whether small electronic components or large mechanical parts, it can be handled easily

In general, visual glue filling machine realizes precise control and automatic operation of glue filling process through visual detection and intelligent control. It not only improves the production efficiency and product quality, but also greatly reduces the error and labor intensity of manual operation.

中文

中文