How to ensure the quality of automatic glue filling machine

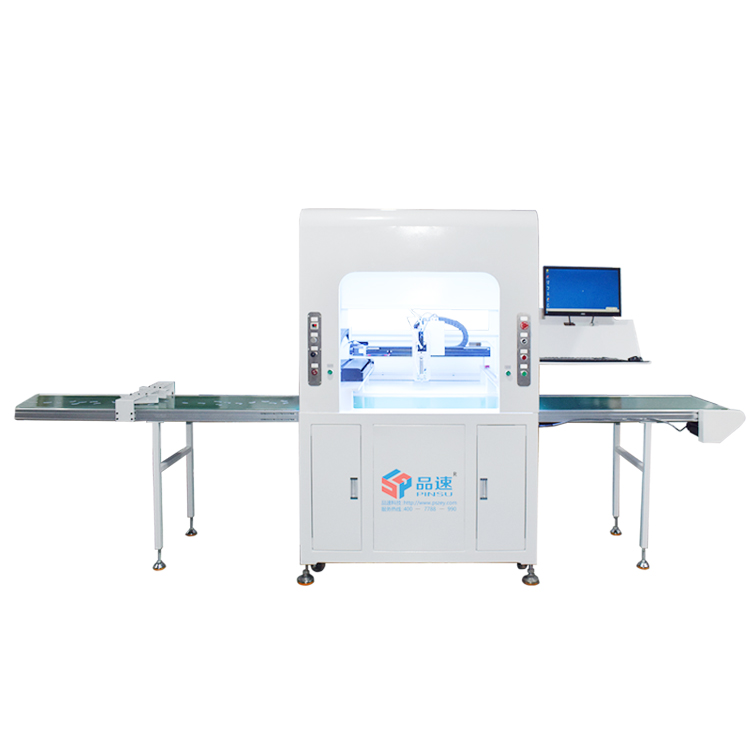

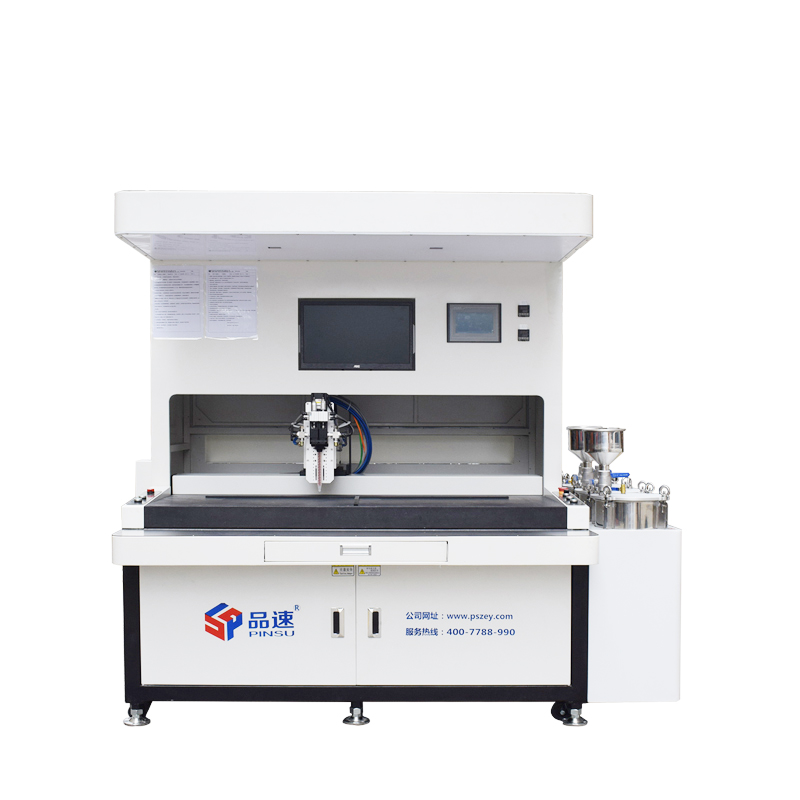

As the booster for industrial production, the importance of automatic glue filling machine is self-evident. To ensure the quality of automatic glue filling machine is the key to ensure its stable operation in the production process and improve the production efficiency.

1. Strict raw material selection is the basis to ensure quality. High-quality raw materials ensure the reliability and durability of automatic glue filling machine. The raw material supply of PinGum Potting Machine is a long-term cooperation with regular manufacturers, and its performance and stability are guaranteed.

2. Sophisticated production process is the core to ensure quality. In the production process, Pinxi Dispenser strictly controls every link, from parts processing to the whole machine assembly, all strictly abide by the quality standards.

3. Comprehensive quality inspection is an indispensable link. Upon the completion of production, Pinxi Dispenser shall conduct comprehensive quality inspection, including performance test, reliability test, etc., to ensure compliance with relevant standards and requirements.

4. A professional technical team is an important support to ensure quality. PinDispenser has a professional technical team, which can provide professional technical support in R&D, production and after-sales links, solve various technical problems and ensure the quality and performance of the automatic Dispenser.

5. Good after-sales service is the extension of quality. PinDispenser can timely respond to customers' demands and provide high-quality after-sales services, including installation, commissioning, training, maintenance, etc.

Only through strict raw material selection, exquisite production process, comprehensive quality inspection, professional technical team and good after-sales service can the quality of automatic glue filling machine be stable and reliable and create greater value for customers.

中文

中文