What are the factors that affect the dispensing effectiveness of the Dispenser?

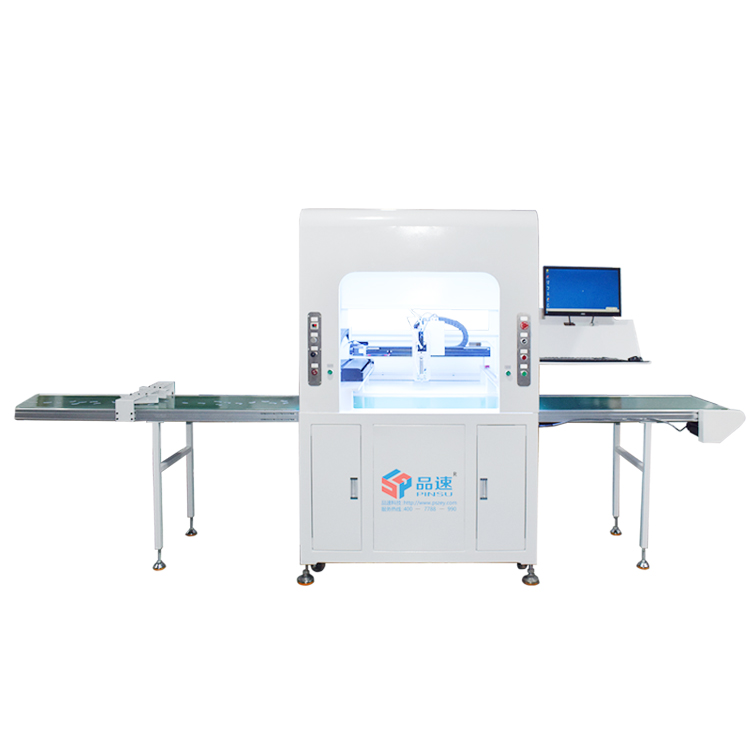

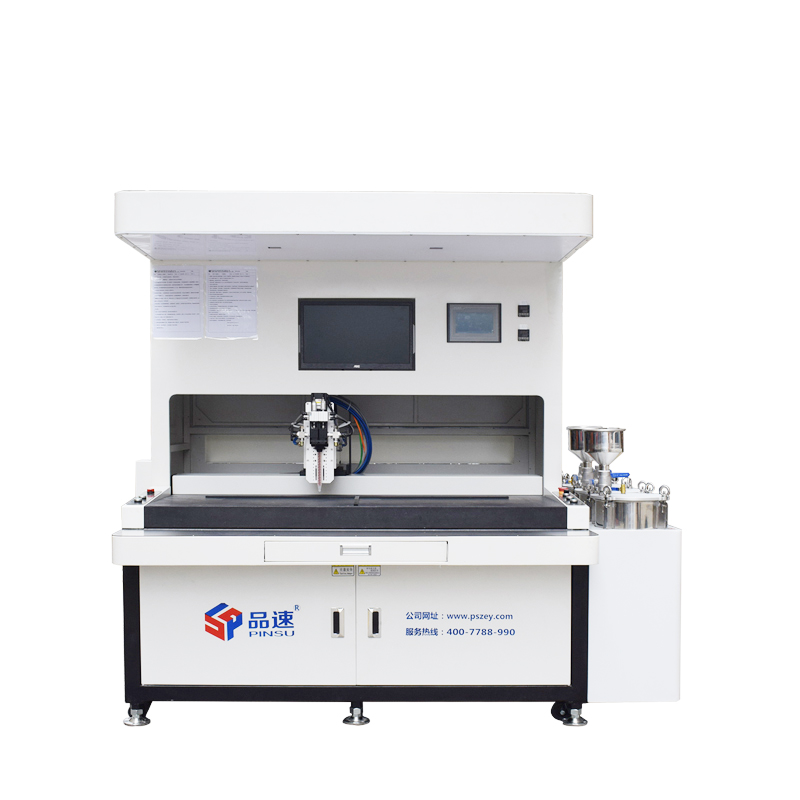

Dispensing machines are widely used in various fields, especially in industrial production and assembly processes. Therefore, for the needs of production and processing, the selection of the dispensing machine is very important to ensure the relevant work, and is an important consideration factor for process optimization. The best selection should start from measuring the dispensing effect of the dispensing machine. What factors affect the dispensing effectiveness of the Dispensing Machine?

1.Glue amount: It is generally considered that the diameter of the glue point shall be half of the product spacing to ensure that the adhesive amount of the adhesive binding component is sufficient to prevent excessive adhesive amount. The amount of glue depends on the length of time. In actual application, the gluing time shall be selected according to the temperature and characteristics of glue.

2.Glue viscosity: Generally, the viscosity of glue will directly affect the quality of glue. If the viscosity is very high, the binding point will be very small, and string will occur. If the viscosity is low, the bonding point will become bigger, which may pollute the product, so the bonding temperature shall be kept within this range. Viscosity affects the equipment, resulting in a decrease in temperature and an increase in viscosity, which in turn reduces the flow of adhesive, making stringing more likely. In practice, the adhesive shall be cured at the highest possible temperature to provide sufficient strength after curing.

3.Dispenser Needle: Typically, select a needle with an inside diameter of approximately half the dispensing diameter. During dispensing, select the dispensing needle according to the size of the product.

4.Dispensing pressure: Generally, excessive pressure will cause overflow and excessive glue volume. If the pressure is too low, there will be intermittent leakage, which may cause product defects, so it shall be judged according to the ambient temperature and adhesive viscosity.

5.Distance between the needle and the working surface: different dispensing machines use different needles. Some needles have a certain gear, so the dispensing interval must be well controlled, and the distance between the needle and the working surface must be prepared in advance for each dispensing. The beginning of a work. Interval calibration, i.e. Z-axis height calibration.

The above 5 points may affect the dispensing effect of the dispensing machine. In the actual production process, we can use the above points to find out the problems that affect the effect of the dispensing machine.

1.Glue amount: It is generally considered that the diameter of the glue point shall be half of the product spacing to ensure that the adhesive amount of the adhesive binding component is sufficient to prevent excessive adhesive amount. The amount of glue depends on the length of time. In actual application, the gluing time shall be selected according to the temperature and characteristics of glue.

2.Glue viscosity: Generally, the viscosity of glue will directly affect the quality of glue. If the viscosity is very high, the binding point will be very small, and string will occur. If the viscosity is low, the bonding point will become bigger, which may pollute the product, so the bonding temperature shall be kept within this range. Viscosity affects the equipment, resulting in a decrease in temperature and an increase in viscosity, which in turn reduces the flow of adhesive, making stringing more likely. In practice, the adhesive shall be cured at the highest possible temperature to provide sufficient strength after curing.

3.Dispenser Needle: Typically, select a needle with an inside diameter of approximately half the dispensing diameter. During dispensing, select the dispensing needle according to the size of the product.

4.Dispensing pressure: Generally, excessive pressure will cause overflow and excessive glue volume. If the pressure is too low, there will be intermittent leakage, which may cause product defects, so it shall be judged according to the ambient temperature and adhesive viscosity.

5.Distance between the needle and the working surface: different dispensing machines use different needles. Some needles have a certain gear, so the dispensing interval must be well controlled, and the distance between the needle and the working surface must be prepared in advance for each dispensing. The beginning of a work. Interval calibration, i.e. Z-axis height calibration.

The above 5 points may affect the dispensing effect of the dispensing machine. In the actual production process, we can use the above points to find out the problems that affect the effect of the dispensing machine.

中文

中文