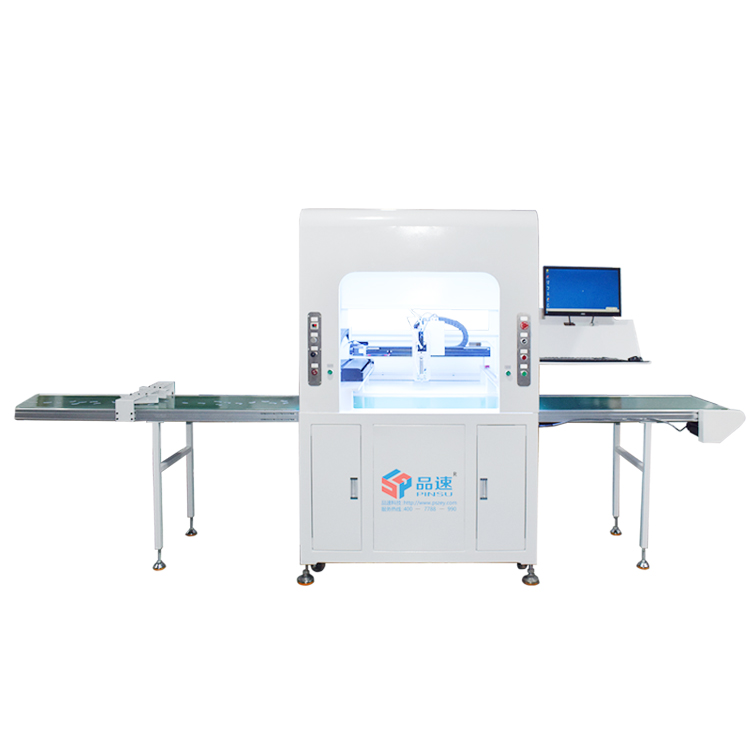

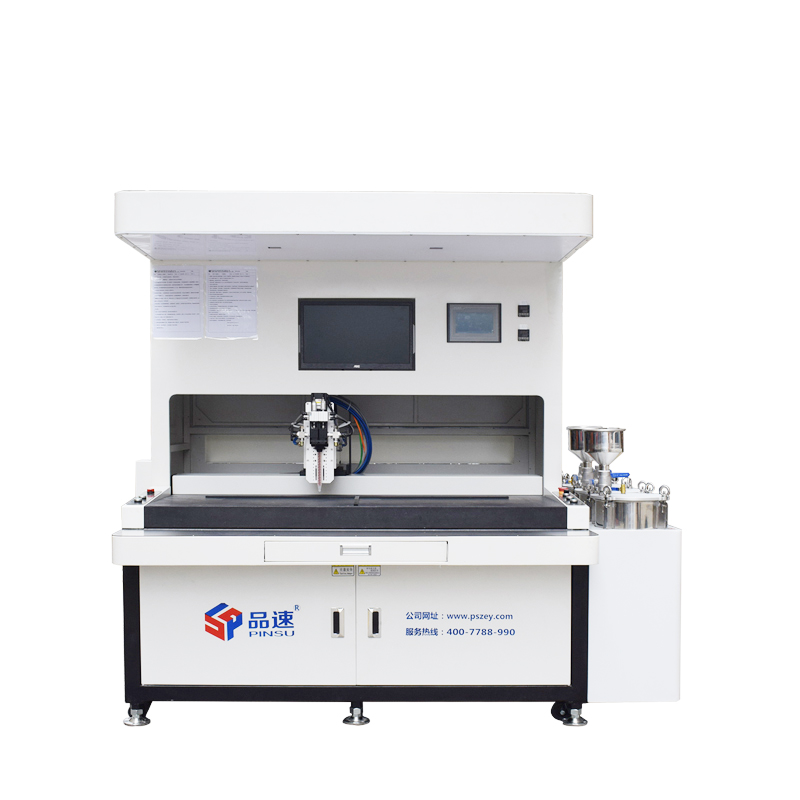

How to prevent the glue filling machine from blocking during use

When manufacturing enterprises are using glue filling machine for production, sometimes they will encounter blocking situation, glue cannot come out, or glue amount is small, which will affect production or cause quality problems. How to solve this situation to prevent blocking?

First of all, we should know why the blockage occurs. The causes of blockage are as follows:

1.Too much powder and too large particle in glue will cause glue precipitation and serious blockage.

2.Blockage caused by impurities in glue.

3.Blockage caused by glue crystallization.

The above is the main cause of the blockage. After knowing the cause of the rubber plug, let's talk about the solution.

1.Try to use better glue, one price for one product. Good glue will make the filler very thin and the filling point is relatively low. But those too cheap glue will make the filler much and the particles are very coarse.

2.When pouring glue, filter it with a filter. Some very large particles of impurities will be filtered off. Otherwise, when some large impurities enter the pipe or enter the glue valve, they will be blocked on the pipe due to too large volume to discharge, resulting in glue failure or small glue amount.

When the manufacturing enterprises can handle the most likely blocking problem in the working process of glue injection equipment, it can not only improve our production efficiency, but also guarantee the product quality.

中文

中文